(Click the table of contents to navigate to the detailed content)

1. Introduction

2. Design Code

(1) In South Korea

(2) Overseas Design Code

3. Design Case

(1) Cable Stayed Bridge

(2) Suspension Bridge

4. Calculation of the pylon drag coefficient according to the design code

(1) Comparison of drag coefficients

(2) Calculation of drag coefficient using cross-sectional ratio (D/B) in Eurocode

(3) Estimation of drag coefficient through wind tunnel experiment

5. Conclusion

1. Introduction

Wind load is often the dominant load in the case of long span cable and suspension bridge pylons, and accordingly, the importance of the drag coefficient applied to calculate the wind load acting on the pylons is great.

Therefore, we reviewed the direction of applying the drag coefficient of pylon in the future by referring to design cases based on domestic and international design standards.

2. Design Code

(1) In South Korea

- Design Standards for Road Bridges (Limit State Design Method) - General Bridge

According to the Design Standards for Road Bridges (Limit State Design Method) - General Bridge Section 3.13.2.3 Wind Pressure acting on substructures, it is stated that "For circular and trapezoidal sections, a factor of 0.6 can be used, while for angular sections, a factor of 1.2 can be used."

-

Design Standard for Road Bridges (Limit State Design Method) - Cable Bridge

According to the Design Standards for Road Bridges (Limit State Design Method) – Cable-Stayed Bridge Section 8.6.2 Static Wind Loads on Main Members, it is stated that "The values obtained from wind tunnel tests or numerical analysis are used. However, if wind tunnel tests are not conducted, it must be demonstrated that the drag coefficient Cd applied in the design is reasonable."

-

Design Criteria for Road Bridges (2008)

According to the commentary 2.1.11(6) of the Road Bridge Design Standards (2008), "0.8 is used for circular and track-type cross sections and 1.6 is used for square cross sections.

For other shapes, it may be determined appropriately by the judgment of the technician."

(2) Overseas Design Code

- Design Standard for Honshu Shikoku Bridge Corporation

The drag coefficient for a rectangular cross-section is defined as 1.8.

This value is approximately calculated by applying corrections based on the aspect ratio of 8 to 40 to the drag coefficient value of 2.1, which corresponds to the case where the long side of the rectangular cross-section (2:1) faces the wind.

Honshu Shikoku Bridge

Honshu Shikoku Bridge

-

Eurocode

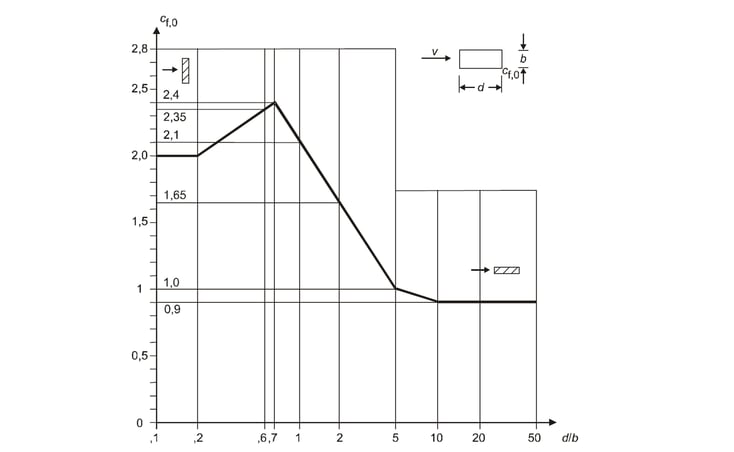

The drag coefficient of the square part of the structural element where the wind blows at right angles to the plane is calculated using the following graph.

EUROCODE 1991-4 General actions - Wind actions, 7.6 Structural elements with rectangular sections

Applying the coefficient of reduction for a square with rounded corners.

3. Design Case

The drag coefficients of the main towers of cable-stayed and suspension bridges designed in South Korea mostly apply values of 1.6 or 1.8. In cases where separate wind tunnel tests have been conducted, the drag coefficients determined by those wind tunnel tests have been applied.

And this value is generally calculated smaller than the drag coefficient presented in the design criteria.

(1) Cable Stayed Bridge

(2) Suspension Bridge

4. Calculation of the pylon drag coefficient according to the design code

(1) Comparison of drag coefficients

(2) Calculation of drag coefficient using cross-sectional ratio (D/B) in Eurocode

%EB%A5%BC%20%EC%9D%B4%EC%9A%A9%ED%95%9C%20%ED%95%AD%EB%A0%A5%EA%B3%84%EC%88%98%20%EC%82%B0%EC%A0%95.png?width=734&height=475&name=7.%20Eroucode%EC%97%90%EC%84%9C%20%EB%8B%A8%EB%A9%B4%EB%B9%84(DB)%EB%A5%BC%20%EC%9D%B4%EC%9A%A9%ED%95%9C%20%ED%95%AD%EB%A0%A5%EA%B3%84%EC%88%98%20%EC%82%B0%EC%A0%95.png)

(3) Estimation of drag coefficient through wind tunnel experiment

After installing the load cell on the model, the air force (drag force) generated at this time is measured by applying a wind having a constant wind speed.

After that, the drag coefficient of the model cross section is calculated through the relationship equation below.

Source: http://www.tesolution.com

5. Conclusion

If a separate drag coefficient measurement experiment is not conducted, the drag coefficient according to the Eurocode is too conservative, and it is somewhat ambiguous about whether and how to apply effects such as chamfering.

As can be seen from the case of calculating the pylon drag coefficient through wind tunnel experiments, the chamfering of the cross section is expected to reduce the drag coefficient by 15 to 30%, but it is difficult to apply it numerically uniformly because it depends on the chamfer shape and size.

Ignoring the shape ratio of the pylon's cross-section and the presence of Chamfer, applying a uniform drag coefficient of 1.8 can be safe from a design perspective, but it may also become excessively uneconomical.

Therefore, it is reasonable to accurately measure the drag coefficient of the pylon cross section through wind tunnel experiments or computational fluid dynamics analysis and reflect it in the design in order to properly reflect the characteristics of the pylon cross section.

CFD analysis is also performed to calculate characteristic values such as the drag coefficient of the pylon. CFD analysis has the advantage of being able to obtain the result value quickly because it takes less time and cost compared to wind tunnel experiments. However, in the end, it is common to compare the result value with the wind tunnel experiment to verify the validity of the characteristic value obtained through CFD analysis.

In the case of special bridges with pylons such as cable-stayed bridges and suspension bridges, wind tunnel tests must be performed under the relevant design laws. It is not difficult to add a partial model experiment such as a tower girder under these prepared wind tunnel experimental conditions, which is reasonable in terms of economic and temporal terms.

#Drag coefficient

#Wind load

#Bridge pylons

/Y.S.LEE_346_240.png)

For over 10 years, I have been involved in diverse structural design tasks related to bridges, underground passages, noise barriers, and more.

I am an experienced user of Midas Civil for structural analysis, as well as other Midas programs such as Midas FEA and Midas CIM.

※ Click on the keywords below 'Topics' to view related content.

![Design and Practical Examples of Baseplates and Anchor Rods [sample download]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC22.png)

![Understanding Drafting Standards [ Drawing download ]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC24.png)

![Key Changes in ACI 318-19: A New Standard for Structural Design [ PDF download]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC21-1.png)

![Design and Practical Examples of Lug design(ASME BTH-1) [sample download]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC20-1.png)