There are times when engineers would have to design and evaluate bridge structures that fall outside of the AASHTO design guideline. Therefore, when do we define a structure as irregular? How is evaluating an irregular bridge different from evaluating a regular bridge? How to minimize errors during the construction of irregular bridges? We invited midas expert Percy Penafiel, Professional Engineer Specialist from Nevada Department of Transportation, to answer some of the frequently asked questions from our users regarding evaluating irregular bridge structures.

Q: The difference between evaluating a regular bridge structure and an irregular bridge structure?

Percy: Several bridges that I have been working on while at Nevada DOT were highly skewed, that's why I have used midas to design those bridges using grillage model. I prefer using grillage model to plate and solid element model because I think the design outputs are really easy to manipulate and visualize in midas Civil using its grillage model.

Percy: But first, let's talk about how AASHTO recommends what to consider as regular bridge structure.

-

-

-

-

Plan Aspect Ratio: Regular if length > 2.5 Width (Spring model) (AASHTO 4.6.1.1)

-

Curved in Plan: Regular if maximum subtended angle (in curved bridge) is less than 30° (Guide Specs Table 4.2.3)

-

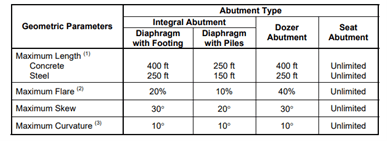

The two tables below also define the requirements for regular bridges.

-

-

-

Percy: In this table below, in case we have very high skew bridges, it shows the plot of dead load shear and resistance factors (y-axis) vs skew angle (x-axis), where the y-axis ranges from 0.7 - 1.6 for I-Girder factor, and 0.4 - 2.2 for Box Girder factor. x-axis ranges from 0° - 60°. Beyond the scope of this table, you would need to use more sophisticated methods to evaluate the structure. To answer your question "what's the difference between evaluating a regular bridge structure and an irregular bridge structure", if you evaluate a bridge with skew angle of 60° as a regular structure, you use the magnification factor of 1 of the exterior girder instead of 2.2 from the table below, and that will cause a significant difference.

Dead load shear and resistance factors for skewed bridges, where the y-axis ranges from 0.7 - 1.6 for I-Girder factor, and 0.4 - 2.2 for Box Girder factor. x-axis ranges from 0° - 60°

Dead load shear and resistance factors for skewed bridges, where the y-axis ranges from 0.7 - 1.6 for I-Girder factor, and 0.4 - 2.2 for Box Girder factor. x-axis ranges from 0° - 60°

Q: How can errors in construction lead to structural issues? If an irregular geometry is modeled in a certain way, how can errors in construction lead to problems in the original structural model?

Percy: When it comes to irregular structure, the construction plan has to be really detailed. This entails detailed and necessary notes to guide the contractor through the construction stages I have designed. For example, as shown in the image below, the longitudinal main girders (red) are post-tensioned. The long bend cap (green) is also post-tensioned. Therefore, there should be a sequence regarding performing the post-tensioning to those structure, and they should be detailed by the engineers in the notes given to the contractors. Also, someone has to be on the field to make sure contractors follow the note to minimize errors.

Percy: Another example will show the communication between engineers and contractors is vital to ensure the irregular bridge structures are constructed to standard of initial design. The image below shows the plan view of a highly skewed bridge structure with monolithic construction consists of concrete boxes and very strong diaphragm. Due to the high skew angle, welded bar is designed at the end because high stress concentration is produced due to the high skew angle. Also, due to the geometry, the bars are designed to be welded. If the contractor does not see this notes, the bars and the bridge deck would not be able to take the moment produced. The distribution of the force would also be drastically different, and engineers would need to re-analyze the structure to look for alternative design solutions based on the current construction. Therefore, not providing details as shown on plans can lead to structural issues because the distribution force will change and thus overstressing other sections of the bridge.

/Percy%20Penafiel%20240_240.png)

He has 20+ years of structural engineering experience, primarily in the structural design of highway bridges, pedestrian bridges, and railroad bridges. He is also skilled in drainage structures like culverts and channels, structural supports for highway signs, luminaires, traffic signals, and toll gantries. His experience also includes portal tunnels, soil nail walls, tie-back walls, MSE walls, retaining walls, and sound walls.

![Design and Practical Examples of Baseplates and Anchor Rods [sample download]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC22.png)

![Understanding Drafting Standards [ Drawing download ]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC24.png)

![Key Changes in ACI 318-19: A New Standard for Structural Design [ PDF download]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC21-1.png)

![Design and Practical Examples of Lug design(ASME BTH-1) [sample download]](https://2495902.fs1.hubspotusercontent-na1.net/hubfs/2495902/%EC%8D%B8%EB%84%A4%EC%9D%BC20-1.png)