Introduction

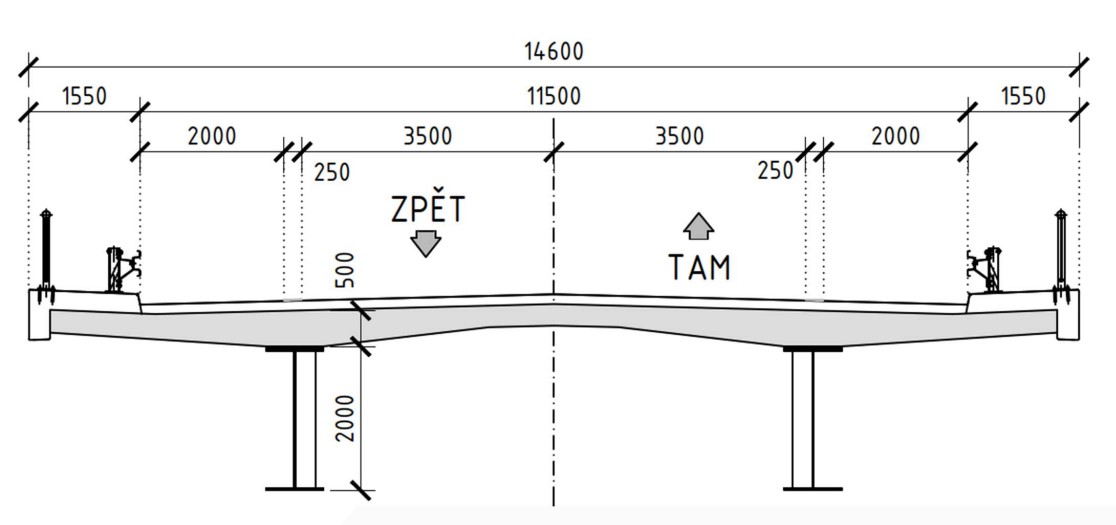

Bridges are not just functional transport structures; they are testaments to human engineering prowess. Particularly in the realm of composite steel-concrete bridges, the intricacies of design play a pivotal role in ensuring safety, durability, and aesthetics. With examples like the bridge over the Kremlice brook and the bridge near Pasohlávky, we can gain a clear understanding of how composite bridge design is evolving.

The Foundations of Composite Bridge Design

1. Modeling Basics:

Steel-Concrete Bridges: Modern bridges often use a blend of steel and concrete, maximizing the strengths of both materials.

Critical Construction Phases: It's imperative to consider the entire lifecycle, from initial construction to potential renovations.

Addressing Deformations: Composite RC slabs will undergo deformation and shrinkage. These natural reactions to stress and environment need to be predicted and accounted for.

Cracks in Concrete: No material is immune to wear and tear. Computational models must anticipate potential cracks in the concrete slab.

2. The Role of Midas Civil: Midas Civil is a prominent tool in the world of engineering, offering solutions for elastic designs, especially for bridges with section classes 3 and 4.

Example solution in midas Civi

Example solution in midas Civi

3. The Construction Phase:

Cross-Section Analysis: Whether for pure steel or a composite of steel and concrete, understanding the cross-section is vital.

Longitudinal Analysis: The bridge's length, divided into fields (FIELD 1, FIELD 2, and FIELD 3), needs separate attention to ensure even stress distribution and overall stability.

Diving Deeper into Design Nuances

-

Crack Management: Reinforced concrete slabs might develop cracks. Specific models, such as the one accounting for "15% L" tearing according to EN 1994-2, help assess and mitigate these concerns.

-

Midas Civil Solutions: From phased cross sections to computational models, Midas Civil offers a wizard for steel composite bridges. While manual modeling is an option, tools like these can optimize the design process.

-

Data Input with MCT Command: Precision is key. Engineers can input specific data commands to refine their models further.

-

Section Sizing: Both automated tools like Midas Civil and manual post-processing, perhaps in tools like MS Excel, allow engineers to size sections correctly.

-

Final Evaluations: Once the design is complete, engineers must determine the composite's effects and understand relationships, such as Grashof's for shear flow. The effective use of normal force in the concrete slab becomes crucial.

Conclusion

Composite steel-concrete bridge design is an art and science combined, demanding precision, innovation, and a deep understanding of materials and forces. With tools like Midas Civil and tried-and-true methodologies, engineers today are better equipped than ever to craft bridges that stand the test of time. As we reflect on the intricacies of such designs, we're reminded of the power of engineering to shape our world, one bridge at a time.

Pavel Kaláb, a Product Engineer at IDEA StatiCa since October 2022, brings over 14 years of experience in bridge and structural engineering from his ongoing role with Stráský, Hustý and Partners in Brno, Czech Republic. His expertise is highlighted in his published article "When a shear connection transmits a bending moment" and his contributions to webinars on composite steel-concrete bridges and Midas Civil. Pavel's deep understanding of structural engineering principles is evident in his professional and academic endeavors.