Intro

Concrete is the predominant building material in modern architecture. The oldest concrete discovered was in the floor of a hut in Israel, dated around 7000BC. Concrete has been used for centuries. However, due to its weakness in tension, reinforced concrete with steel bars is widely used today. Did you know that this reinforced concrete was born from a broken flowerpot?

*This post is based on a video created by Tyler Ley, a professor with over 20 years of engineering experience.

Inventing Unbreakable Flowerpots: Joseph Monier's Concrete Innovation

French gardener Joseph Monier developed reinforced concrete in 1867. He was frustrated with his clay flowerpots constantly breaking. To prevent the pots from easily shattering, he reinforced them with wire mesh and concrete to enhance their strength. While the pots still broke occasionally, the cracks were much smaller than before. The addition of steel reinforcement helped supplement the weakness in tension of concrete, reducing the occurrence of cracks.

Joseph Monier (1823-1906) and patent for Reinforced Concrete

Joseph Monier (1823-1906) and patent for Reinforced Concrete

Where reinforcement is needed?

We need to reinforce where cracks occur. So, where do cracks typically form?

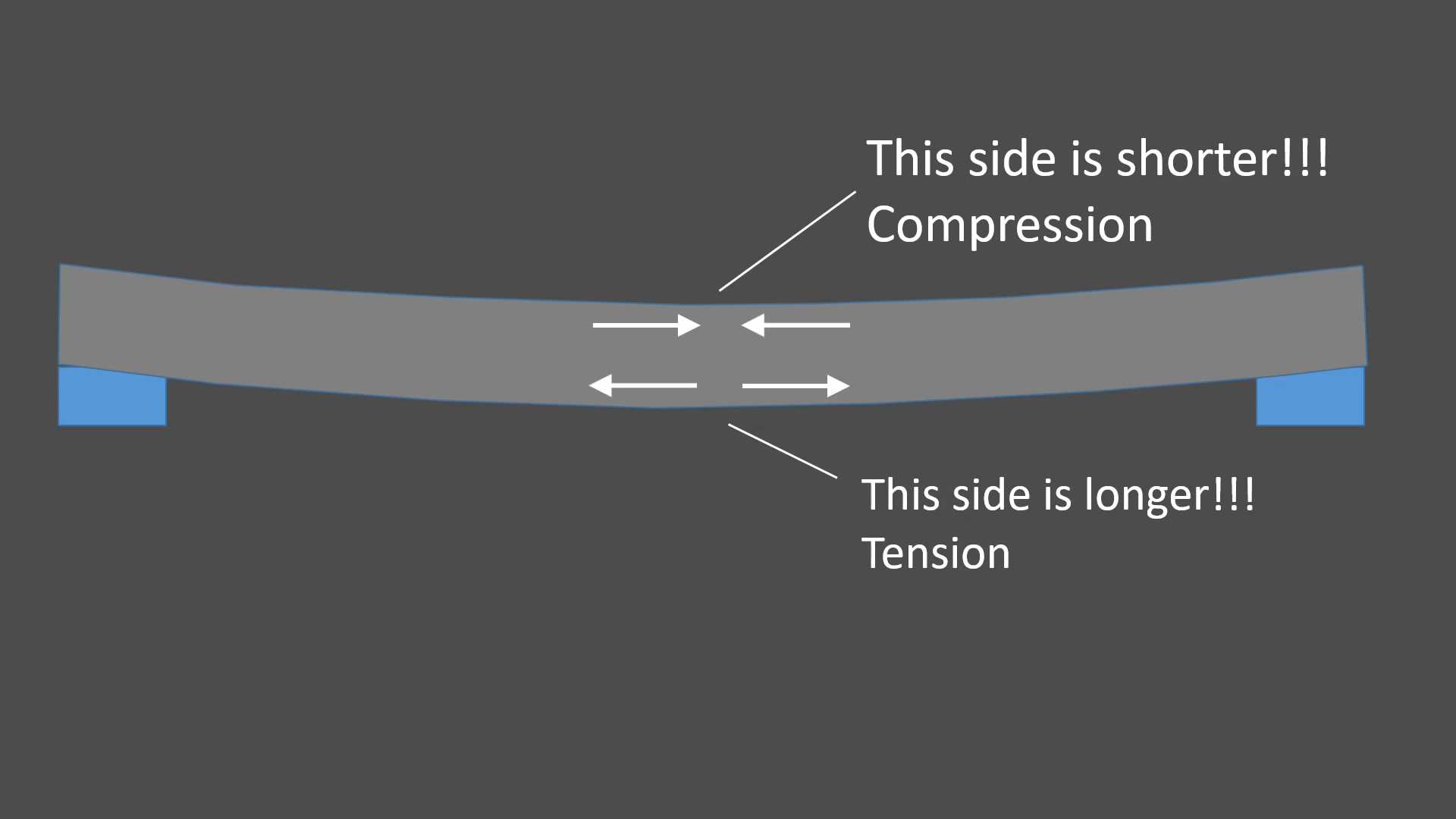

The answer lies in areas where concrete is trying to get longer. This is called tension. When bending occurs due to a load, as in the example of the beam below, the top part tends to shorten while the bottom’s gonna be getting longer. Therefore, reinforcement with steel bars is done at the bottom.

Top - Compression / Bottom - Tension

Top - Compression / Bottom - Tension

Put the reinforcement at the tension face.

Put the reinforcement at the tension face.

Ideally, it would be great to have steel reinforcement placed very close to the surface. However, we have to be careful not to place them too close because it can lead to corrosion.

How much reinforcement is needed?

Though there is reinforcement inside the concrete, those cracks they still form but they become smaller. The size of cracks should be ideally less than 0.04 inches according to ACI 350 standards. (ACI 350 = American Concrete Institute's standards for the design of concrete structures)"

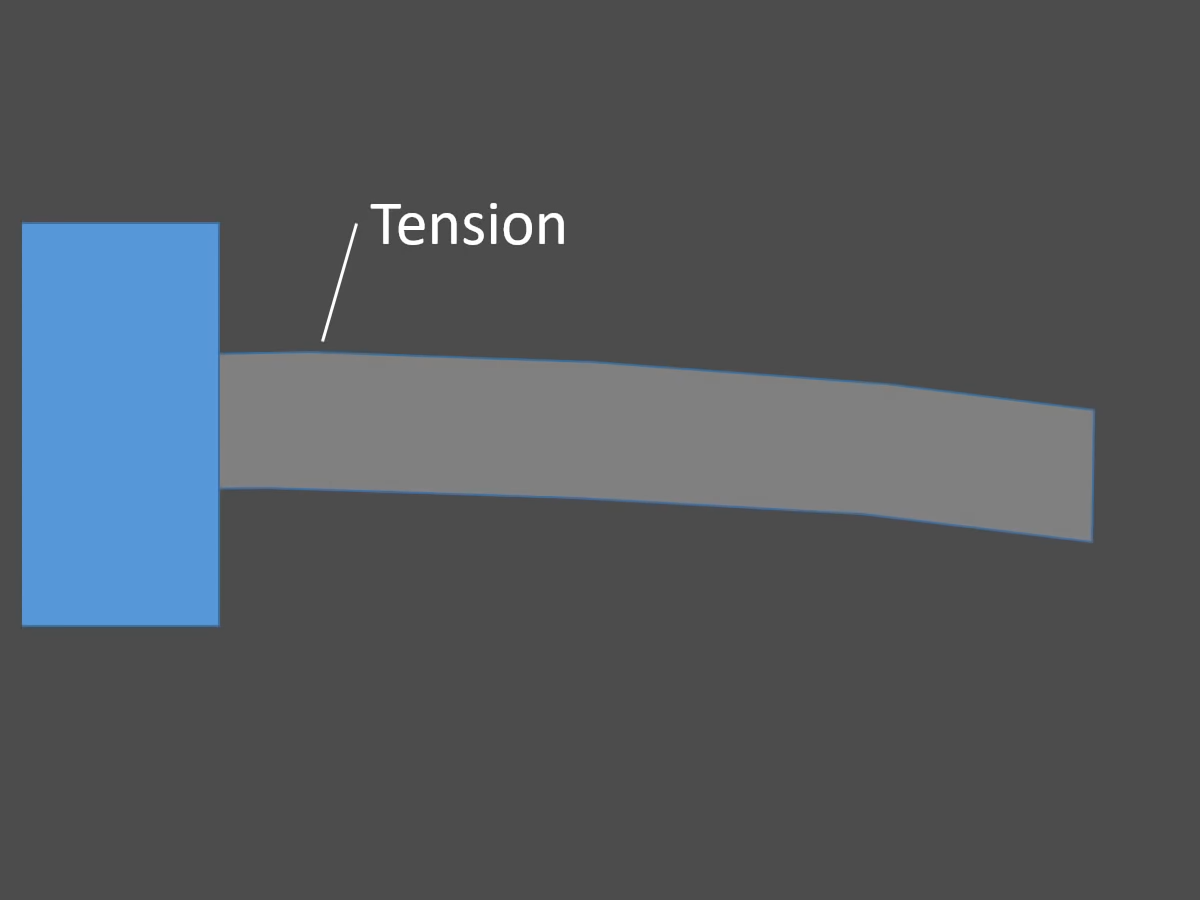

Example 1 : Cantilever

Where should you reinforce a cantilever? Consider how concrete will move. Since tension occur at the top, you should reinforce the top, not the bottom.

Tension occurs at the top

Tension occurs at the top

Reinforcement at the top where tension occurs

Reinforcement at the top where tension occurs

Example 2 : Mixed

Then, where should the beam like the one below be reinforced?

Always where tension occurs.

Conclusion

In summary, concrete is prone to cracking due to its weakness in tension, and reinforcing with rebar at the locations where tension occurs can minimize cracks. The location of tension varies depending on the structure's form. Current skyscrapers and bridges built with reinforced concrete might have been constructed much later if Joseph Monier, who wanted to strengthen flowerpots, didn't exist.

For more detailed explanations and examples, check out Tyler Ley's original YouTube video, which is the motive of this post, by clicking this link : Secrets of Reinforcement | How to design reinforced concrete

The world needs your ideas and inspiration. MOTIVE is building a platform that inspires and grows engineers through knowledge sharing. If you want to share an idea that inspires someone and contributes to creating a better world, become a MOTIVATOR. You might be the next Joseph Monier.

References

Tyler Ley's original video : Secrets of Reinforcement | How to design reinforced concrete

History of Concrete - The Irish Concrete Society

Amusing Planet - François Coignet’s Reinforced Concrete House

/Tyler%20ley%20240_240.png)

I have more than 20 years of experience in the fields of structural and concrete materials engineering. During this time I have worked as an engineer with a design consultant, construction contractor, government agency, and as a professor. This practical experience has made me a better teacher and researcher.

I am very active in the American Concrete Institute where I am a voting member of the Concrete Durability, Material Science, Concrete Proportioning, and Sustainability Technical committees. In addition, I serve on the executive committee of the National Concrete Consortium, a group made up of DOT engineers from 35 different states. I also served as the president of the American Ceramics Society Cements Division in 2016. I have a passion for creating innovative learning content.

My websites are visited by over 50,000 people per year, visit my website and youtube. (👈click)

※ If you click on the keywords below "Topics," you can view related contents.

/%EC%9E%91%EC%9D%80%EC%97%B0%EB%AA%BB_400_400.png)